Home > Special machines

Special machines

Producer of special machines

The heart of our business is the design and production of special machines.

Learn more about our special machinesHigh speed assembly machine, jointing machine, palletiser, marking machines of all types (hot stamping, pad printing, silk screen printing) etc…

Established in the Plastics Valley since 2001, DMA Groupe implements everything to support you in the equipment of your industrial sites.

Thanks to a team of about 45 people, we design and manufacture your special machine.

We offer solutions ranging from independent machines to fully integrated and custom-designed lines.

All of them offer the rigorous quality and know-how of DMA Groupe.

Objectives

By setting up a relationship of listening and trust with our customers, we want to be your permanent partner for your facilities with a simple objective: working in the long term.

Construction & integration

-

Our boilermaking workshop coupled with our workshops for machining, assembly, wiring and automation are the framework for the realization of your projects.

- Internal realization of chassis, machining and assembly of mechanical parts

- Design and realization of automation and electrotechnical architecture

- Integration of vision system for control and automatic sorting (dimensional, appearance, assembly …)

- Integration of robots for handling, assembly, gluing, and packaging operations

-

Your equipment is developed in our premises. Their performances are tested in accordance with the specifications and are the subject of a pre-acceptance at our premises.

- Commissioning within your organization by us

- Training, technical assistance by our teams

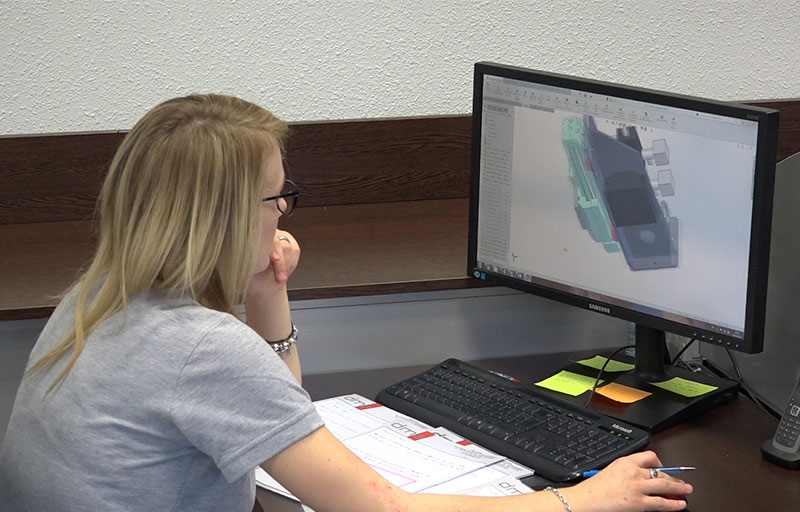

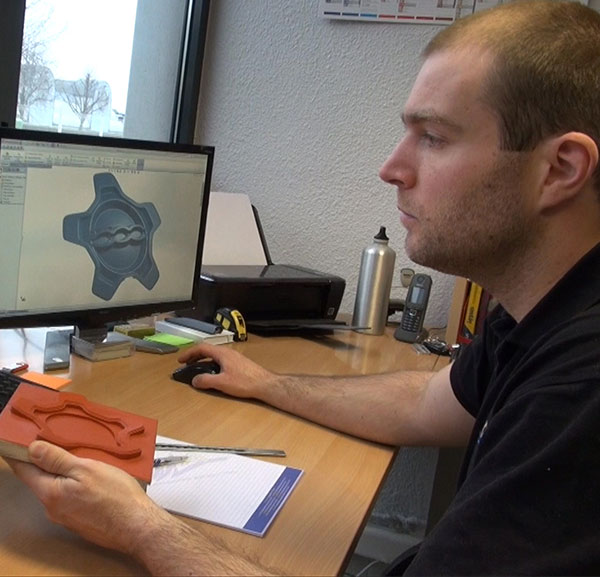

Design and Engineering

Our design office brings you all its know-how.

For this, our team of professionals is listening to you in order to advise you, accompany you and implement your project.

From a defined need or a specification, the project manager implements all the most adapted technical solutions.

Mastering the software SOLIDWORK, he is your sole interlocutor throughout the realization and oversees all phases from the design to commissioning.

Sectors of activity

-

COSMETICS INDUSTRY

Mascaras, Lipsticks, Powder, Sticks, Pumps, Plastic and Glass Vials, Pots, Lid -

PHARMACEUTICAL INDUSTRY

Pipettes, syringes etc…. -

AUTOMOTIVE INDUSTRY

Buttons, drain oil caps, rim inserts etc… -

VARIOUS INDUSTRY

Pallet, technical parts electrical appliances, …

Some examples of special machines

Marking machine, joining machine, assembly or pad printing machines...

Find our special machines designed in our design office and produced in our workshops for boiler making, machining, assembly and wiring.

-

STANDARD HOT STAMPING MACHINE

-

HOT MARKING MACHINE

-

PAD PRINTING MACHINE

-

DROPPER BOTTLE ASSEMBLY MACHINE

-

VALVE ASSEMBLY MACHINE FOR 8-COMPONENT DIFFUSER

-

VISION + PACKING MODULE

-

MATRIX CUTTING MACHINE ON LOGO WEB

-

CORK GLUING + ASSEMBLY MACHINE

-

SPECIFIC ASSEMBLY MACHINE

-

ASSEMBLY AND MARKING MACHINE

STANDARD HOT STAMPING MACHINE

Description

- Digital marking head with ball screw

- Numercial foil management

- Stamping force up to 1200 kg (Higher capacity optional)

- Standard DMA adjustable ball head equipped with comparator

- Stamping of parts at 300°C

- Functions configurable via touch display

- Safety light curtain

- Mechanically welded machine frame, user-friendly, robust and aesthetic

- Base plate suitable for all types of toolings

Options

- Possibility of customization and option.

- Supply of tools, stamp development and preliminary design decor testing on request.

HOT MARKING MACHINE

Description

- 6 CNC marking heads

- Electrical axis for CNC longitudinal carriage

- Film pulling

- Part marking at 300°C

- Function configuration using 2 touch-screen interfaces

- Rate: 40 sec/part

Options

- Safety light curtain barriers

- Operator present sensor

- Dust removal station

- Suction unit

- Marking pressure sensor

PAD PRINTING MACHINE

Description

- 2 pad printing heads with 3 DMA CNC axes

- 1 CNC pad printing assembly with Staubli TX2-40 6-axis robot

- 4 infra-red heating tunnels

- Front/reverse product decoration

- Function configuration using 12" touch-screen interface

- Human-machine interface moves around machine

Options

- 3D plasma treatment with TX2-60 6-axis robot

- Parts transferred directly to painting chain with TX2-90L 6-axis robot

- Conveyor between machines

- Bulk unloading on belt conveyor

- Remote control

DROPPER BOTTLE ASSEMBLY MACHINE

Description

- 3 components loaded using vibrating bowl + hopper

- Machine autonomy: 1 hour

- Rate

- Loaded using DMA CNC cam manipulator

- Loaded using DMA CNC 2-axis cam manipulator

- Handles glass dropper + breakage check + part not blocked check

- Bulk unloading + bulk carton management

- Function configuration using 12" touch-screen interface

- Human-machine interface moves around machine

Options

- Handles glass dropper + breakage check + part not blocked check

- Can support + supply 4th part (scalable machine)

- Positioning by numerical rotation

- Boxing check

- Introduction of interface for part loading and unloading with palletiser

- Remote control

VALVE ASSEMBLY MACHINE FOR 8-COMPONENT DIFFUSER

Description

- 8 components loaded using vibrating bowl + hopper

- Machine autonomy: 1 hour

- Rate 1400 p/h

- Loaded using DMA CNC cam manipulator

- Mechanical crimping by deformation

- 100% of valves receive operating check

- Bulk unloading

- Function configuration using 12" touch-screen interface

- Human-machine interface moves around machine

Options

- Component lubrication with volume micro-dosing and dose analysis

- Boxing and mechanical crimping checks

- Remote control

VISION + PACKING MODULE

Description

- Thermal wrap magazine

- Visual checks (top/contour)

- Carton feed/evacuation by conveyor

- Rate 3000 parts/hour

- Layered packing in carton

- Thermally wrapped packing in carton

Options

- Function configuration using touch-screen interface

MATRIX CUTTING MACHINE ON LOGO WEB

Description

- Semi-automatic machine

- Webs loaded by operator

- Parts unloaded by 6-axis robot with bulk sorting of logos into 16 containers

- Matrix waste unloaded by 6-axis robot into 600 x 800 bin

- Cutting uses pneumatic matrix cutters with numerical right/left movement

Options

- Function configuration using touch-screen interface

- Centralised suction to remove plastic shavings

- Dual cutting knives to reduce cycle time

CORK GLUING + ASSEMBLY MACHINE

Description

- Automatic machine

- Rate 1000 p/h

- Corks loaded using vibrating bowl

- Integration of thermoformed tray storage magazine

- Thermoformed tray loaded by robot TS2-80

- Corks loaded on to bucket by belt conveyor

- Application of ring of hot glue

Options

- Function configuration using touch-screen interface

- Integration of forced laminar airflow to ensure positive pressure inside the machine

- Hydraulic hopper can be raised to enable loading access

SPECIFIC ASSEMBLY MACHINE

Description

- High speed assembly : gluing, end rolling, ultrasonic welding, clipping

- Distribution by feed bowl or robot (4, 6 axes)

- Thermo palletising

- Mechanical or optical indexing

- Functions programmable by a tactile display

- Rate: 1000 to 8000 parts/hour

Options

- Lubrication

- Mechanical or optical control

- Printing module (pad printing, screen printing, hot marking)

- Robotic unit

ASSEMBLY AND MARKING MACHINE

Description

- Assembly of six components per stick

- encasing

- Screwing

- Digital printing module hot marking and screenprinting

- Distribution by feed bowl or robot (4, 6 axes)

- thermo palletising

- Mechanical or optical indexing

- Functions fully programmable by a tactile display

- Rate : 1500 pces/hour

Options

- Printing module (pad printing, screen printing, hot marking)